Down Stage Right Industries

Theatrical and Entertainment Rigging Hardware

Shackle Plates NEW! from TheatricalHardware.com

There are five uniquely different designs in the Shackle Plates™ Dynasty. Each one allows you the freedom of choice as you design the rigging requirements of your scenery, as well as meeting the changing needs of every production.

Quick and easy to use. Choose th e best suited Shackle Plate™ for your project and simply attach it by bolting to the lowest point of the scenery directly in line with the Keeper Plate™ that you have bolted to the top of the scenery. The cable line used to suspend the scenery is attached to the Shackle Plate™ and then run though the Keeper Plate's™ eye opening and finally onto the suspending point. Now you're ready to go.

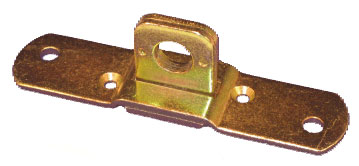

Shackle Plate™ 1/2” Hole Part # 2010

Made from heavy-gauge steel and pre-drilled for assembly with two 1/4” bolts and two #8 or #10 fl at head screws.

Will accept shackles or jaw type turnbuckles with a 1/2” through-bolt and mounts easily to the bottom-rail of any flat or for use as a floor or ceiling plate.

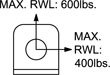

IT'S RATED !

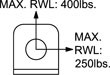

90° Shackle Plate™ Part # 2020

Made from heavy-gauge steel and pre-drilled for assembly with two 1/4” bolts. Mounts easily to the side-stiles of any wood or metal flat.

IT'S RATED !

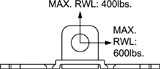

90° Shackle Plate™ Stubby Part # 2030

Made from heavy-gauge steel and pre-drilled for assembly with two 1/4” bolts. This smaller version of the 90-degree Shackle Plate™ will mount easily and more discreetly into the side-stiles of any wood or metal flat.

IT'S RATED !

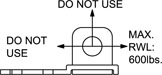

1/2” Hole Shackle Plate™ Stubby Part # 2060

Made from heavy-gauge steel and pre-drilled for assembly with two 1/4” bolts. Smaller version of the 1/2” Shackle Plate™ that will mount easily and more discreetly into the bottom-rail of any wood or metal fl at, and can also be used as a fl oor or ceiling plate.

IT'S RATED !

Keeper Plate™ Stubby Part # 2050

Made from heavy-gauge steel and pre-drilled for assembly with two 1/4” bolts.

Attach the Keeper Plate™ Stubby at the top of the scenery directly in line with the Shackle Plate™ that you have bolted to the lowest point of the piece. The cable line used to suspend the scenery is attached to the Shackle Plate™ and then run though the Keeper Plate’s™ eye opening and finally onto the suspending point

Keeper Plate™ Part # 2040

Made from heavy-gauge steel and pre-drilled for assembly with two 1/4” bolts and two #8 or #10 fl at head screws.

Attach the Keeper Plate™ at the top of the scenery directly in line with the Shackle Plate™ that you have bolted to the lowest point of the piece. The cable line used to suspend the scenery is attached to the Shackle Plate™ and then run though the Keeper Plate’s™ eye opening and finally onto the suspending point.

Welding Bolt Plate™ Part # 3050

Made from 1/8” heavy-gauge steel.

Use this trouble-free plate to attach one piece of scenery to another. Weld the square end onto your steel scenery making sure that the rounded end with the hole is exposed. Now your other scenery can be bolted directly to the plate.

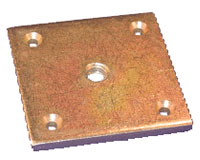

Threaded Square Plate™ Part # 3010

Made from 1/4” heavy-gauge steel.

Pre-drilled and tapped for a 3/8-16 bolt with four counter-sunk holes for #8 or #10 fl at head screws

Photo Examples of Shackle Plates in use! (Click Here)

Shackles

We offer drop forged, quenched and tempered screw pin anchor shackles as our standard but we will provide safety as well as other types of shackles on request. Working load limits are stamped into each shackle. We recommend the use of shackles in overhead lifting because they are rated for this with a built in 5:1 safety factor. We ordinarily sell Crosby shackles.

|

Nominal Size (in.) | Working Load Limit (t)* | Stock No. | Weight Each (lbs.) | Dimensions (in.) | Tolerance +/ | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G-209 | S-209 | A | B | C | D | E | F | G | H | L | M | P | C | A | ||||

| 3/16 | 1/3 | 1018357 | — | .06 | .38 | .25 | .88 | .19 | .60 | .56 | .98 | 1.47 | .16 | 1.12 | .19 | .06 | .06 | |

| 1/4 | 1/2 | 1018375 | 1018384 | .10 | .47 | .31 | 1.13 | .25 | .78 | .61 | 1.28 | 1.84 | .19 | 1.38 | .25 | .06 | .06 | |

| 5/16 | 3/4 | 1018393 | 1018400 | .19 | .53 | .38 | 1.22 | .31 | .84 | .75 | 1.47 | 2.09 | .22 | 1.66 | .31 | .06 | .06 | |

| 3/8 | 1 | 1018419 | 1018428 | .31 | .66 | .44 | 1.44 | .38 | 1.03 | .91 | 1.78 | 2.49 | .25 | 2.03 | .38 | .13 | .06 | |

| 7/16 | 1-1/2 | 1018437 | 1018446 | .38 | .75 | .50 | 1.69 | .44 | 1.16 | 1.06 | 2.03 | 2.91 | .31 | 2.38 | .44 | .13 | .06 | |

| 1/2 | 2 | 1018455 | 1018464 | .72 | .81 | .63 | 1.88 | .50 | 1.31 | 1.19 | 2.31 | 3.28 | .38 | 2.69 | .50 | .13 | .06 | |

| 5/8 | 3-1/4 | 1018473 | 1018482 | 1.37 | 1.06 | .75 | 2.38 | .63 | 1.69 | 1.50 | 2.94 | 4.19 | .44 | 3.34 | .69 | .13 | .06 | |

| 3/4 | 4-3/4 | 1018491 | 1018507 | 2.35 | 1.25 | .88 | 2.81 | .75 | 2.00 | 1.81 | 3.50 | 4.97 | .50 | 3.97 | .81 | .25 | .06 | |

Quicklinks

Quick links are not recommended for overhead lifting by the manufacturer, but are often used because of their convenience. Please keep in mind the working load limits when using quick links. If in doubt, use a shackle. We can supply batch tested as well as the Original Malion Rapide individually tested quick links. Mallion Rapide quick links are manufactured by Péguet and Cie which was founded in 1941 as a family-owned company and now has a presence in more than 50 countries world-wide. The big strength of the Maillon Rapide (Quick Link) lies in its effectiveness. Despite their small size, they have a matchless strength, further checked by traction tests during the whole manufacturing process. Safety margin is 5 times the guaranteed working load limit (WLL).

| Size | Working Load Limit | ||

|---|---|---|---|

| metric | imperial | lbs | kg |

| 4mm | 1/8" | 220 | 100 |

| 5mm | 3/16" | 660 | 300 |

| 6mm | 1/4" | 880 | 400 |

| 8mm | 5/16" | 1760 | 800 |

| 9mm | 3/8" | 2200 | 1000 |

| 10mm | 7/16" | 2600 | 1200 |

| 12mm | 1/2" | 3300 | 1500 |

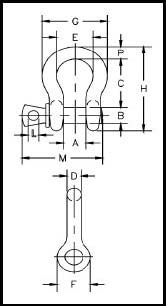

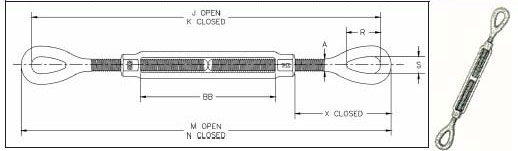

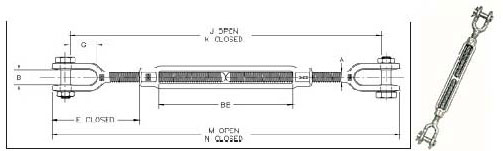

Turnbuckles

Turnbuckles are available in a wide variety of sizes and styles. The most commonly used in the theatre are shown below, but we do carry larger sizes and other styles. Available in eye to eye, jaw to jaw, or hook to hook. These are all drop forged galvanized items. Both Crosby and offshore products are available.

Eye & Eye

| Thread Diameter x Take up (in.) | Stock No. Galv. | Working Load Limit (lbs.) | Weight Each (lbs.) | Dimensions (in.) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | J Open | K Closed | M Open | N Closed | R | S | X Closed | BB | ||||

| 1/4 x 4 | 1031252 | 500 | .26 | .25 | 11.80 | 7.80 | 12.25 | 8.25 | .78 | .34 | 1.75 | 4.00 |

| 5/16 x 4 1/2 | 1031270 | 800 | .45 | .31 | 13.56 | 9.06 | 14.12 | 9.62 | .94 | .44 | 2.09 | 4.50 |

| 3/8 x 6 | 1031298 | 1200 | .76 | .38 | 17.47 | 11.47 | 18.16 | 12.16 | 1.12 | .53 | 2.52 | 6.00 |

| 1/2 x 6 | 1031314 | 2200 | 1.54 | .50 | 20.08 | 13.08 | 20.96 | 13.96 | 1.44 | .72 | 3.23 | 6.00 |

| 1/2 x 12 | 1031350 | 2200 | 2.14 | .50 | 32.08 | 19.08 | 32.96 | 19.96 | 1.44 | .72 | 3.23 | 12.00 |

Jaw & Jaw

| Thread Dia. x Take up (in.) | HG-227 Stock No. | Working Load Limit (lbs.) | Weight Each (lbs.) | Dimensions (in.) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | E Closed | G | J Open | K Closed | M Open | N Closed | R | S | X Closed | BB | ||||

| 1/4 x 4 | 1031877 | 500 | .30 | .25 | .45 | 1.58 | .62 | 11.35 | 7.35 | 12.07 | 8.07 | .78 | .34 | 1.75 | 4.00 |

| 5/16 x 4 1/2 | 1031895 | 800 | .50 | .31 | .50 | 1.98 | .87 | 13.71 | 8.71 | 14.01 | 9.51 | .94 | .44 | 2.09 | 4.50 |

| 3/8 x 6 | 1031911 | 1200 | .80 | .38 | .54 | 2.12 | .87 | 16.81 | 10.81 | 17.77 | 11.77 | 1.12 | .53 | 2.52 | 6.00 |

| 1/2 x 6 | 1031939 | 2200 | 1.51 | .50 | .65 | 2.75 | 1.06 | 19.29 | 12.29 | 20.48 | 13.48 | 1.44 | .72 | 3.23 | 6.00 |

| 1/2 x 9 | 1031957 | 2200 | 1.71 | .50 | .65 | 2.75 | 1.06 | 25.29 | 15.29 | 26.48 | 16.48 | 1.44 | .72 | 3.23 | 9.00 |

| 1/2 x 12 | 1031957 | 2200 | 2.08 | .50 | .65 | 2.75 | 1.06 | 31.29 | 31.29 | 32.48 | 19.48 | 1.44 | .72 | 3.23 | 12.00 |

Stage Hardware

D Rings & Top Hanging Irons

These items are manufactured as a tie off or attachment point for rigging hardware. Shown below are D Ring (most economical), top hanger, bottom hanger and ceiling plate.

D Ring with Plate

1 -1/8 w x 4 ¾” h Plate

2” w x 1-5/8” h Ring

Top Hanging Iron

9” x 1- 1/8” wide

2” wide ring

Bottom Iron

6-7/8” overall x 1” wide

Ceiling Plate

Hinges

We offer loose pin, tight pin and sure hinges for your scenic and or construction projects

1 1/2" Loose Pin

2" Loose Pin

1 1/2" Tight Pin

2" Tight Pin

1 1/2" Sure Hinge

Eye Bolts

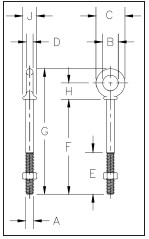

G-277 Shoulder Nut Eye Bolts

Shoulder Eye bolts should be utilized whenever there are angular lifts involved

| Shank Diameter & Length (in.) | G-277 Stock No. Galv. | Working Load Limit (lbs.) | Weight Per 100 (lbs.) | Dimensions (in.) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | ||||

| 1/4 x 2 | 1045014 | 650 | 6.60 | .25 | .50 | .88 | .19 | 1.50 | 2.00 | 2.94 | .50 | .47 |

| 1/4 x 4 | 1045032 | 650 | 9.10 | .25 | .50 | .88 | .19 | 2.50 | 4.00 | 4.94 | .50 | .47 |

| 5/16 x 2-1/4 | 1045050 | 1200 | 12.50 | .31 | .62 | 1.12 | .25 | 1.50 | 2.25 | 3.50 | .69 | .56 |

| 5/16 x 4-1/4 | 1045078 | 1200 | 18.80 | .31 | .62 | 1.12 | .25 | 2.50 | 4.25 | 5.50 | .69 | .56 |

| 3/8 x 2-1/2 | 1045096 | 1550 | 21.40 | .38 | .75 | 1.38 | .31 | 1.50 | 2.50 | 3.97 | .78 | .66 |

| 3/8 x 4-1/2 | 1045112 | 1550 | 25.30 | .38 | .75 | 1.38 | .31 | 2.50 | 4.50 | 5.97 | .78 | .66 |

| 1/2 x 3-1/4 | 1045130 | 2600 | 42.60 | .50 | 1.00 | 1.75 | .38 | 1.50 | 3.25 | 5.12 | 1.00 | .91 |

| 1/2 x 6 | 1045158 | 2600 | 56.80 | .50 | 1.00 | 1.75 | .38 | 3.00 | 6.00 | 7.88 | 1.00 | .91 |

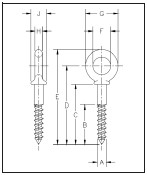

G-275 Screw Eye Bolts

Lag Eyes for a secure mounting into substantial wood framing are a great tool for the rigging kit.

| Shank Diameter & Length (in.) | G-275 Stock No. Galv. | Weight Per 100 (lbs.) | Dimensions (in.) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | |||

| 1/4 x 2 | 1046111 | 4.30 | .25 | 1.50 | 2.00 | 2.50 | 2.94 | .50 | .88 | .19 | .47 |

| 5/16 x 2-1/4 | 1046139 | 9.90 | .31 | 1.69 | 2.25 | 2.94 | 3.50 | .63 | 1.13 | .25 | .56 |

| 3/8 x 2-1/2 | 1046157 | 18.88 | .38 | 1.88 | 2.50 | 3.28 | 3.97 | .75 | 1.38 | .31 | .66 |

| 1/2 x 3-1/4 | 1046175 | 37.50 | .50 | 2.44 | 3.25 | 4.25 | 5.12 | 1.00 | 1.75 | .38 | .91 |

| 5/8 x 4 | 1046193 | 85.50 | .63 | 3.00 | 4.00 | 5.31 | 6.44 | 1.25 | 2.25 | .50 | 1.12 |

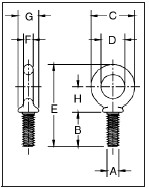

Shoulder Type Machinery Eye Bolts

S-279 UNC

| Size | S-279 Stock No. | Working Load Limit (lbs.) | Weight per 100 (lbs.) | Dimensions (in.) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A** Thread | B | C | D | E | F | G | H | ||||

| 1/4 x 1 | 9900182 | 650 | 5.00 | 1/4 - 20 | 1.02 | 1.13 | .75 | 2.29 | .19 | .53 | .70 |

| 5/16 x 1-1/8 | 9900191 | 1200 | 9.00 | 5/16 - 18 | 1.15 | 1.38 | .88 | 2.74 | .25 | .59 | .90 |

| 3/8 x 1-1/4 | 9900208 | 1550 | 15.00 | 3/8 - 16 | 1.27 | 1.62 | 1.00 | 3.07 | .31 | .69 | 1.00 |

| 1/2 x 1-1/2 | 9900217 | 2600 | 28.00 | 1/2 - 13 | 1.53 | 1.95 | 1.19 | 3.70 | .38 | .91 | 1.20 |

M-279 Metric

| Size | M-279 Stock No. | Working Load Limit (kg) | Weight Each (kg) | Dimensions (mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A** Thread | B | C | D | E | F | G | H | ||||

| M6 x 1.0 | 1045753 | 200 | .03 | M6 x 1.0 | 13.0 | 28.7 | 19.1 | 49 | 4.9 | 13.5 | 21.7 |

| M8 x 1.0 | 1045789 | 400 | .05 | M8 x 1.25 | 13.0 | 35.1 | 22.4 | 56 | 6.4 | 15.0 | 25.5 |

| M10 x 1.5 | 1045833 | 640 | .07 | M10 x 1.5 | 17.0 | 41.1 | 25.4 | 64 | 7.9 | 17.5 | 26.5 |

| M12 x 1.75 | 1045869 | 1000 | .11 | M12 x 1.75 | 20.5 | 49.5 | 30.2 | 78 | 9.7 | 23.1 | 32.8 |

Chain

There is a wide variety of sizes and styles of chain on the market. Great care should go into the selection of the appropriate chain for your application. We stock the most useful types for the entertainment industry.

Jack Chain

Is a twisted non-welded loop style of chain useful for very light duty suspension not requiring high strength. Often used in the support of curtain track or drapes from carriers.

| Size | Max Dia | Inside length | WLL (lbs) |

|---|---|---|---|

| #8 | .16 | 1.09 | 60 |

| #10 | .14 | .93 | 43 |

| #12 | .11 | .75 | 29 |

| #14 | .08 | .63 | 16 |

| #16 | .06 | .5 | 10 |

Double Loop

Is a weldless knotted style of low carbon steel chain. While it has higher working load limits, its uses are again for very light duty suspension

| Size | Dia | Inside Length | WLL (lbs) |

|---|---|---|---|

| 5 | .06 | .92 | 55 |

| 4 | .07 | 1 | 70 |

| 3 | .08 | 1.1 | 90 |

| 2 | .09 | 1.33 | 115 |

| 1 | .11 | 1.54 | 155 |

| 2/0 | .14 | 2.17 | 255 |

| 3/0 | .15 | 2.17 | 305 |

| 4/0 | .16 | 2.19 | 365 |

| 8/0 | .23 | 2.9 | 705 |

Grade 30

Is a good general purpose chain. It is proof tested to twice its working load limit with a minimum ultimate load of 4 times its working load limit. While not recommended for overhead lifting by the various manufactures it is commonly used in the theatre for the suspension of scenery and pipes due to the ease of attachment of fittings. JR Clancy has come out with the following recommendation from their Chain supplier. "When used within the appropriate work load limits proof coil chain may be used in hanging towing and pulling applications"

| Size | WLL (lbs) |

|---|---|

| 3/16 | 750 |

| 1/4 | 1300 |

| 5/16 | 1900 |

| 3/8 | 2650 |

Grade 80

This is the only grade of chain recommended by the manufactures for overhead lifting. Unfortunately it is very expensive and the attachment of fittings is very particular.

Recommended for overhead lifting applications.

| Chain Size (in.) | Spec. 8 Drum Stock No. | Feet Per Drum | Material Size (in.) | Working Load Limit (lbs.)* | Maximum Inside Length (in.) | Minimum Inside Width (in.) | Maximum Length 100 Links (in.) | Weight Per 100 Ft.(lbs.) |

|---|---|---|---|---|---|---|---|---|

| 9/32 (1/4) | 273527 | 500 | .276 | 3500 | .90 | .34 | 90 | 72 |

| 5/16 | 273536 | 500 | .343 | 4500 | 1.00 | .48 | 100 | 114 |

| 3/8 | 273545 | 500 | .394 | 7100 | 1.25 | .49 | 125 | 148 |

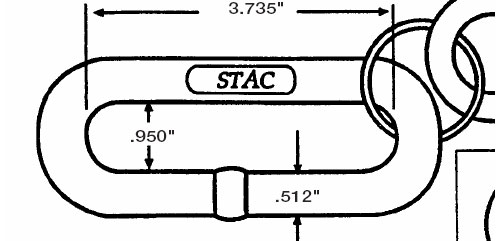

CM Special Theatrical Alloy Chain (STAC)

- Special theatrical alloy chain for rigging applications where bridle adjustability is required

- Adjustable to approximate 4" (100mm), will accept up to a 3/4 inch shackle.

- For adjustment in bridles, also useful for hanging safety steels.

- High strength chain with a working load limit of 12,000lbs, 5900 Kg.

- Made from heat treated alloy steel - fire proof and abrasion resistant.

- Tested and certified, complete with chain tag.

- 4:1 design factor meets N.A.C.M./GR80 standards for strength

- Each link proof tested to assure weld and material integrity

- Chain embossed with STAC and CM for easy identification as CM alloy

- .5750 lbs. per link

- 1.84 lbs. per foot

- Tagged with size, grade, reach and working load limit for positive easy identification

SECOA Theatrical Chain (STC™)

SECOA Theatrical Chain (STC™) is an economical chain designed for overhead lifting applications for the theatrical market.

SECOA Theatrical Chain (STC™) is an economical chain designed for overhead lifting applications for the theatrical market.

FEATURES:

- Rugged, versatile, high strength with low weight.

- The ultimate tensile strength is two and a half times the strength of a standard 1⁄4" proof coil chain.

- Same link size as standard 1⁄4" grade 30 Proof Coil Chain.

- Easily works with existing 1⁄4" chain hardware.

- SECOA Theatrical Chain (STC™) is made from alloy steel for superior performance and strength.

- Working load limit of 3,250 pounds.

- Complies with OSHA 1910.184(e)(5) – Sling use.

- Lot traceable. Every tenth link has a coded date stamp for quality assurance.

- Proof Tested. Every link is proof tested to twice the working load limit.

- Each link is embossed with “STC” for identification.

- Yellow iridescent chromate finish for easy identification.

BENEFITS:

- Safe, reliable and economical.

- High working load limit for safety.

- Easily identifiable in the field.

- Lot traceable.

- Proof Tested.

- Retrofits easily into existing systems for added safety.